Boost Efficiency and Power Transfer With the Best Air Piping Systems

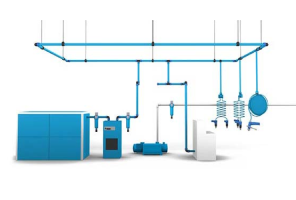

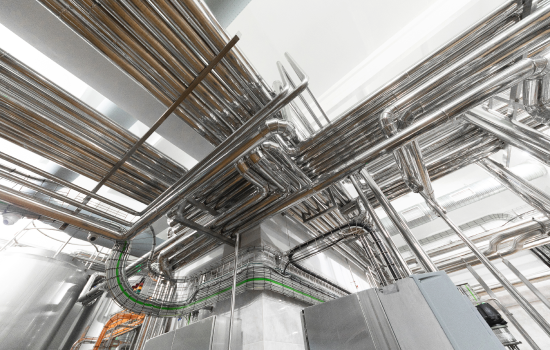

Air piping systems consist of specially designed pipes to minimize pressure drops and ensure optimal power transfer to diverse machinery. While their purpose seems simple—to deliver compressed air where needed—their layout and installation are significant. A poorly designed compressed air piping system can lead to increased energy costs and reduced production efficiencies, which is why the help of experts is essential.

Boost Efficiency and Power Transfer With the Best Air Piping Systems

Air piping systems consist of specially designed pipes to minimize pressure drops and ensure optimal power transfer to diverse machinery. While their purpose seems simple—to deliver compressed air where needed—their layout and installation are significant. A poorly designed compressed air piping system can lead to increased energy costs and reduced production efficiencies, which is why the help of experts is essential.

Get Air Piping Systems From Compresstech

Our experts have the knowledge and experience to help create air piping systems in your facility. We are dedicated to providing only the best and highest-quality products to our clients, so you can rest assured that our installations will be sturdy enough to last for years with proper maintenance.

Air Piping System Parts

Air Piping System Installation

Air Piping System Accessories

How Air Piping Systems Work

What Are the Applications of Air Piping Systems?

High-quality compressed air piping systems can help you with the following:

Power More Tools

Compressed air piping systems enable efficient utilization of air compressors to power tools situated far from the main machine. Some compressors are large and immobile, restricting their reach. With air piping systems, you can extend their functionality, powering tools across your workspace without the need for repositioning heavy equipment.

Save Energy and Time

When set up correctly, air piping systems offer the advantage of simultaneously powering multiple tools. This not only saves energy but also significantly reduces the time required for various tasks. Employees can work efficiently without downtime, enhancing productivity and preventing idle hours in the workplace.

Easy Correspondence

Rather than getting additional air compressors installed in various areas in your facility, installing high-quality air piping systems can be more cost-effective. These systems efficiently deliver compressed air to multiple machines, eliminating the need for extra equipment and contributing to substantial savings in operational expenses.

Talk to Our Experts

For additional information about our offerings, feel free to contact our team today.