Introduction

Compressed air, a versatile and indispensable resource in various industrial applications, is utilized to power machinery and tools. Its quality is paramount regardless of application, as even the smallest impurities affect the efficiency and longevity of equipment.

This is why many facilities have filter/regulator/lubricator (FRL) units to ensure optimal performance in compressed air systems. In this quick guide, we explain the significance of these products and why companies rely on these devices to maintain the quality of their compressed air supply.

Main Components of FRL Units in Compressed Air Systems

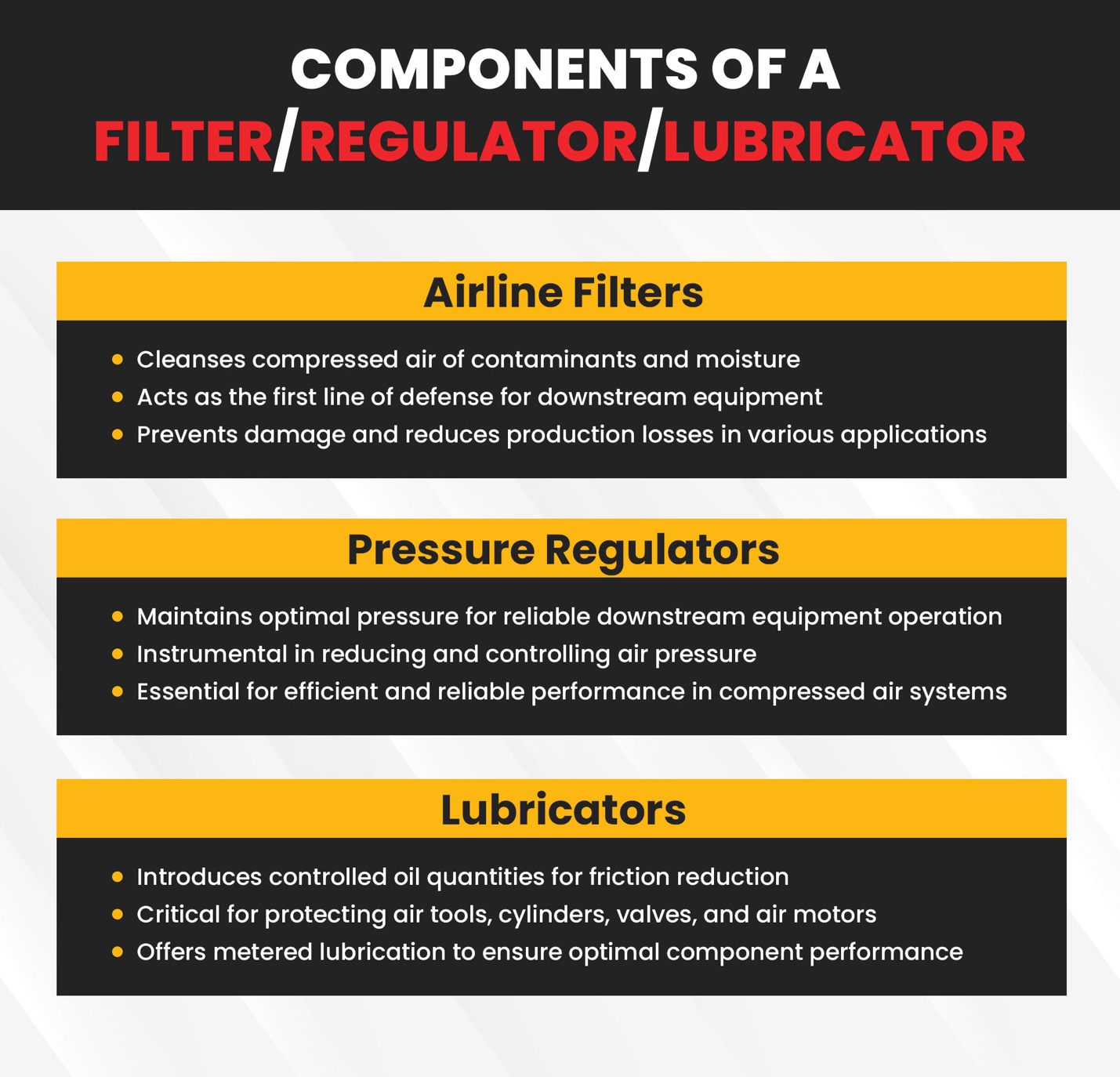

An FRL unit includes the following main components:

Airline Filters

Air leaving a compressor is often laden with heat, contaminants, and moisture—elements that pose a threat to downstream equipment. This is where the crucial role of a compressed air filter in the Philippines comes into play, as it cleanses compressed air by straining out solid particles such as dust, dirt, and rust while separating any liquids like water and oil.

These filters are installed upstream of regulators, lubricators, and various air-driven devices, such as cylinders and air motors, acting as the first line of defense against potential damage to equipment. By removing impurities, airline filters are pivotal in preventing equipment damage and reducing production losses.

Pressure Regulators

Maintaining optimal pressure is paramount for the reliable operation of downstream equipment. Compressed air regulators in the Philippines, also known as pressure-reducing valves (PRVs), are instrumental in reducing and controlling air pressure to meet the specific requirements of various applications within the compressed air system.

Available in relieving and non-relieving types, PRVs play a crucial role in controlling the air pressure sent to pneumatic tools, cylinders, air motors, and various fluidic systems. Understanding the downstream equipment’s flow and pressure requirements is essential for sizing the correct regulator, ensuring efficient and reliable performance in the compressed air system.

Lubricators

Compressed air, though a clean energy source, lacks inherent lubrication, making it essential to introduce controlled quantities of tool oil into the system. Compressed air lubricators in the Philippines address this need by reducing friction in moving components, providing a critical layer of protection for air tools, cylinders, valves, air motors, and other pneumatic equipment.

They offer a controlled and metered supply of lubricant to the air-operated equipment, ensuring that each component receives the right amount of lubrication. Two main types of lubricators cater to different application needs. Oil-fog lubricators are suitable for simple, heavy-duty applications, while micro-fog lubricators are designed for applications with multiple lubrication points.

Why Should You Purchase a Filter/Regulator/Lubricator?

FRL units play an integral role in various facilities as they help achieve the following functions:

Maintain the Overall Quality of Compressed Air

Purchasing an FRL unit is essential to ensure that compressed air supplied to power machinery remains uncontaminated and operates at optimal conditions. In the food and beverage industry, for instance, where hygiene is paramount, these devices play a critical role in ensuring that the compressed air used in food processing remains free from impurities, meeting stringent quality standards.

By adjusting and controlling the compressed air pressure, FRL units also prevent downstream components from being subjected to pressures beyond their maximum operating limits. In the pharmaceutical industry, precise pressure control facilitated by FRL units is crucial in maintaining the integrity of delicate manufacturing processes to ensure the quality and effectiveness of pharmaceutical products.

Eliminate Impurities and Contaminants

Installing FRL units within pneumatic systems helps ensure reliability, power efficiency, and a prolonged component life span. In industries like mining, where heavy-duty equipment operates in challenging environments, these devices become indispensable in preventing damage caused by contaminants, thereby minimizing equipment downtime and maintenance costs.

FRL units are also installed as they diligently remove impurities that could compromise the efficiency of critical machinery. This is particularly vital in the energy and power sector, where turbines and other equipment rely on clean compressed air for optimal performance. By eliminating contaminants, these devices contribute to uninterrupted and efficient power generation.

Keep Your Compressed Air Systems in Optimal Condition

The holistic approach of FRL units in maintaining compressed air systems extends beyond purity and pressure control. The lubricator ensures that the compressed air supply is enriched with a controlled mist of oil. This reduces friction within various equipment used in pneumatic systems, contributing to an extended component life span.

In the steel and metal industry, where heavy machinery is commonplace, FRL units are instrumental in preventing premature wear and tear by providing the necessary lubrication to critical components. Similarly, in the automotive sector, they play a crucial role in sustaining the efficiency of air-driven tools and mechanisms, ensuring smooth operations on the assembly line.

How To Find the Right FRL Unit for Your Compressed Air System

Conduct Preliminary Research

Consider factors like the required pressure range, compressed air flow rate, and any environmental conditions affecting performance, such as temperature or humidity. This preliminary exploration identifies foundational needs, guides your choice, and ensures compatibility and optimal functionality.

Learn About Different Brands

Not all brands are equal, so understanding the reputation, reliability, and performance of each is essential. Browse through user reviews, industry recommendations, and the track record of these brands in delivering durable and effective devices. One name we highly recommend is Ingersoll-Rand ARO, which is available at Compresstech.

Buy From Trusted Suppliers

Lastly, turn to reputable suppliers with a proven history of providing quality products and exceptional customer service. Trustworthy suppliers like Compresstech Resources, Inc. not only offer a diverse range of products but also provide valuable guidance in choosing the suitable unit for your specific application. By prioritizing suppliers with a solid track record, you ensure the authenticity and performance of your FRL unit, contributing to the overall efficiency of your compressed air system.

FAQs About Filter/Regulator/Lubricator Units

How Can You Maintain Your FRL Unit?

Proper FRL unit maintenance is crucial for efficient compressed air systems. Regularly changing the filter cartridge is critical to preventing clogs that lead to power wastage, rust in equipment, and lubrication failures. This is why you must replace the filter element at least once a year and watch for pressure drop indicators, which signal the need for change.

It would be best to inspect the filter bowl for cracks or damage. A defective bowl can cause air loss or pose safety hazards, so opt for durable materials like clear polyurethane or metal-lined bowls for enhanced resistance. Lastly, ensure proper pressure regulation by adjusting the regulator based on needs and manufacturer recommendations. This prevents overconsumption, reduces wear on tools, and saves power.

Which Industries Require FRL Units?

The air leaving a compressor is often hot, dirty, and wet, posing a threat to downstream equipment. FRL units are crucial in preventing damage and extending the life of equipment, which is why companies in various industries such as steel and metal, sugar, construction, automotive, semicon/electronics, and plastic and packaging heavily rely on these devices to maintain efficient and contaminant-free compressed air systems.

What Are the Best Brands of FRL Units?

With various brands to choose from, it may be difficult for some to decide which one to get. Make sure to double-check their reputation online and through industry experts so you can procure high-quality industrial devices for your compressed air system. Some of the most trustworthy names for FRL units include Armstrong, ARO, and Ingersoll-Rand. These brands offer a range of FRL units, ensuring quality and performance for your diverse needs.

Conclusion

For a seamless and efficient compressed air system, reaching out to a reliable filter/regulator/lubricator provider is the key to ensuring optimal performance and longevity of your pneumatic equipment. Whether you want to enhance the purity of your compressed air, regulate pressure precisely, or provide essential lubrication to downstream components, Compresstech Resources, Inc. has you covered.

With a commitment to quality and customer satisfaction, we offer a diverse range of FRL units that seamlessly combine filtration, regulation, and lubrication. Our expertise extends beyond providing top-notch products. We are dedicated to guiding you through the selection process, ensuring that the FRL unit aligns perfectly with your application requirements.

Don’t compromise on the efficiency of your compressed air system. Contact Compresstech Resources, Inc. today for unparalleled FRL solutions tailored to your needs.