Introduction

An oxygen generator is a piece of equipment that separates oxygen from compressed air using pressure swing adsorption, which is a kind of special selective adsorptive technology. When turned on, the machine uses an adsorptive material to remove other gases, such as nitrogen, and allow high-purity oxygen to flow onwards to an outlet.

If you’re looking for one, Compresstech Resources, Inc. can help you. We are an oxygen generator supplier in the Philippines, and we have provided numerous companies with the industrial equipment they have needed over the years. Do not hesitate to contact us today to learn more about what we offer.

The Role of Oxygen in Various Business Processes

Oxygen is one of the most common yet versatile elements in the periodic table. It has a wide range of properties, including paramagnetism and combustibility, which is why it has a range of industrial applications.

Furthermore, this element is available in both gas and liquid states. The former is commonly used in welding, metal manufacturing, bleaching, and cutting, while the latter is primarily utilized as an antioxidant for liquid fuels in the propellant systems of missiles and rockets.

How Does an Oxygen Generator Work?

There are various types of oxygen generators, namely pressure swing adsorption, membrane, and chemical. The most frequently used by companies, however, is the first variation since it has been in existence since the 1970s. Although the machine was improved by numerous professionals as the decades passed, the system used to produce the needed output has mostly stayed the same.

General Components

Oxygen generators are basically a form of chemical engineering that takes advantage of the molecular attraction between gases and adsorbents. Pressure swing adsorption variants separate nitrogen from ambient air inside a pressurized tank filled with the adsorbent material, such as zeolite.

The adsorbent material in an oxygen generator has a large surface area to adsorb more gas molecules. Additionally, it is essential to note that the key to making an efficient generator lies in the adsorbent material used since it needs to utilize one that can effectively adsorb specific components from the air.

When you turn on the unit, compressed air will go into the machine, and the separated gaseous elements will go into their respective storage tanks. It can produce 90% to 95% oxygenated gas, and further refinement can be achieved by repeating the process until an output of 99% is reached. The collected nitrogen can even be used to make other products like nitrous oxide and fertilizer.

Available in Many Forms and Sizes

There are many different types of oxygen generators that you can purchase. However, although portable models that use lithium-ion batteries are convenient, oxygen generators that need to be installed are best suited for industrial applications. These models are able to produce a more considerable amount of refined oxygen in a shorter period and can save you a lot of time.

Worth the Up-Front Costs

Generators may cost more than a single tank or cylinder, but purchasing one is worth the investment if you regularly need refined oxygen. All you need to do is ensure that your employees follow your model’s proper operation, maintenance, and repair procedures so the machine can last for years to come.

What Are the Applications of an Oxygen Generator in the Philippines?

Here are a few applications that commonly use oxygen generators in the Philippines:

General Manufacturing

This industry involves turning raw materials into processed goods on a massive scale. Oxygen generators can be used for a range of production processes, from parts assembly to high technology applications. Furthermore, since some environmental regulations have made it mandatory for industries to reduce their carbon footprint, companies are now focused on introducing the latest technologies to reduce their carbon emissions.

Oxygen generators are used to assist industries in reducing emission levels by providing clean air and helping them comply with the pollution standards set by government bodies. Depending on the industry’s requirements, they come in different sizes and specifications, which can be anything from small general manufacturing units to large industrial plants.

Wastewater Treatment

Oxygen generators are a vital component of wastewater treatment plants. This is because they can provide enough oxygen for the bacteria that break down the organic material in the water. The bacteria then return clean, safe water to the environment.

Aerobic bacteria use up oxygen as they break down organic material in wastewater, so it is important to maintain sufficient dissolved oxygen levels to maintain their activity and prevent long-term sludge accumulation. Aerobic sludge microorganisms also use oxygen during nitrification for denitrification reactions with ammonia-oxidizing bacteria.

Glass Blowing

This high-temperature, high-skill trade involves a proficient craftsman who takes the molten glass from a furnace and shapes it using different tools. Utilizing an oxygen generator, they add gas to molten glass to control the thickness and shape of the resulting object.

When it comes to glass blowing, there are many things you should consider to ensure that your output is of good quality. These factors include whether or not you want bubbles in your glass, what sort of tools you’re using, and what type of surface you’re working with.

Glass is an amorphous and fragile material that needs some type of stabilizer in order to maintain its form. This is why glass blowers typically use a stabilizing gas, such as oxygen or nitrogen. However, some professionals also use a vacuum if they need to achieve a specific shape.

Paper Milling

Delignification is the complex process of removing lignin from the pulp to make paper. This procedure has been used for decades, and it is currently still the most popular way to produce white paper. Although each plant’s specific methodologies would be different, it is often done using a nitrogen and oxygen generator system in a paper mill.

Lignin is a complex organic compound found in plants, giving plant cell walls strength and rigidity. It also helps bind together cellulose fibers in woody plants, making them stronger than they would be otherwise. This material is often removed in the mill as any paper that still has lignin causes all kinds of paper made from wood pulp to weaken and discolor rapidly.

Mining

To break apart large pieces of rocks, miners are often required to use various tools that utilize different gases, such as hydrogen sulfide, nitrogen oxides, and carbon monoxide. These chemical compounds, however, can be dangerous to the human body if inhaled in excessive amounts. This is why companies must supply miners with sufficient oxygen.

The amount of oxygen each worker needs would depend on the composition of gases present. Regardless, the on-site oxygen production will keep each miner safe and ensure that the project is completed with little to no difficulty.

Furthermore, oxygen plays a significant role in the extraction of gold. Industrial mines use the cyanide leaching process, grounding rocks before pouring a sodium cyanide solution to seep into them. To ensure that gold complexes arise as a result of different chemical reactions, professionals add artificial oxygen into the mixture.

Fish Farming

Known as a form of aquaculture, fish farming involves commercially raising fish in large tanks or other enclosures. In most cases, it is done in deep water, with the schools of fish being fed with pellets or small sea animals.

There are many benefits to using an oxygenation system for your fish farming needs. The most significant advantage is that it can increase the amount of time that your fish can live in their tank before they need to be replaced with new ones. This will allow you to make more money without having to invest as much time and energy into caring for them.

Metal Welding

After professionals have discovered numerous other uses for oxygen, this gas has become a raw material that is integral to welding science. It is an essential element in the welding process since it is used to create a hot flame that melts metal, allowing two pieces of this alloy to be fused.

When oxygen is added to the welding torch, it reacts with the other elements and creates an intense blue flame. This oxygen-rich flame can reach temperatures of up to 3,000 degrees Celsius (or 5,432 degrees Fahrenheit). The heat of this flame melts and joins together pieces of metal held in place by a clamping device called a tungsten electrode. This process results in two pieces of metal that are now joined as one and have a smooth surface finish.

Whether you need a nitrogen and oxygen generator for general manufacturing or fish farming, you can be sure that Compresstech can provide you with what you need. We have worked with numerous companies from different industries over the years, and our team is dedicated to helping you attain a machine that meets your needs and preferences. Furthermore, we offer some of the most impressive industrial oxygen generator prices in the Philippines. Reach out to us today to learn more about how we can assist you.

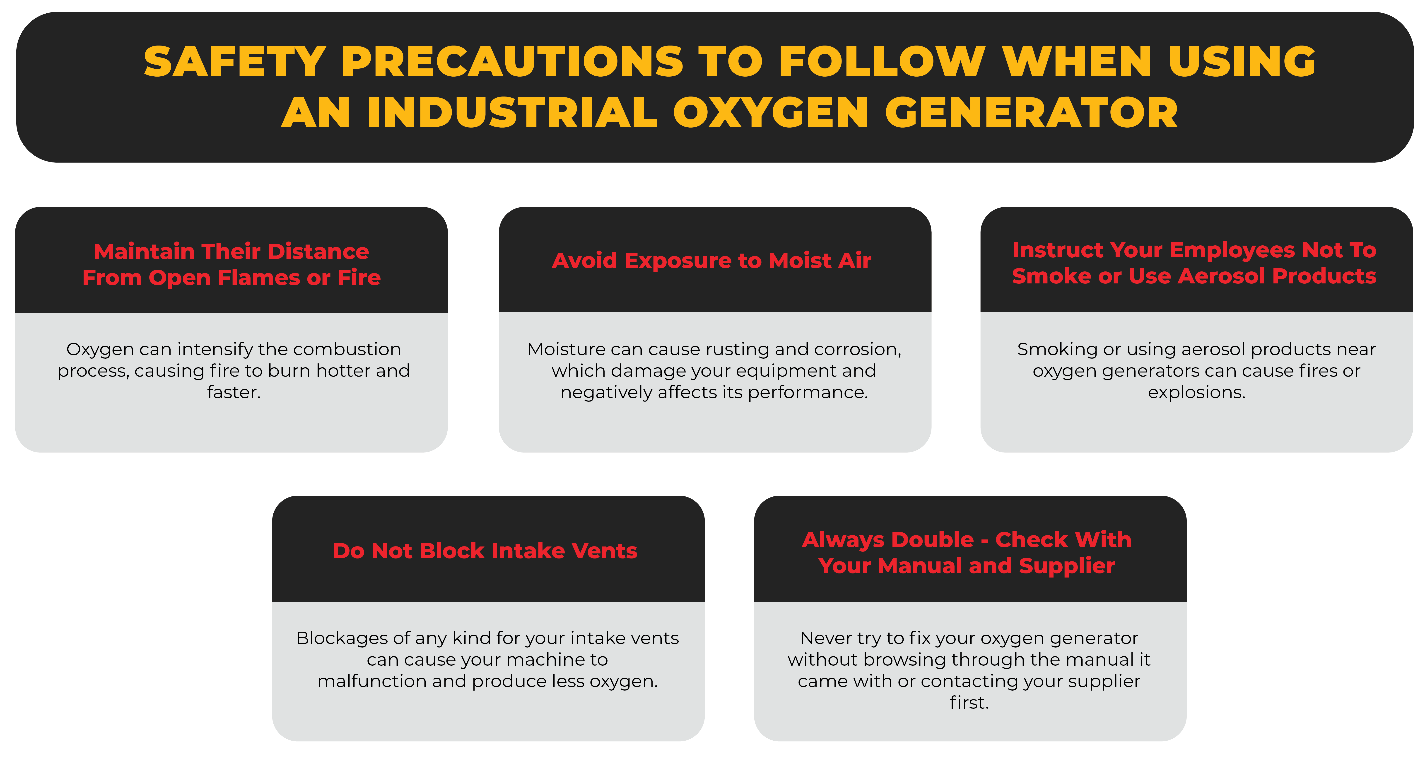

What Are the Safety Precautions When Using an Industrial Oxygen Generator?

If you’re using a machine provided by an oxygen generator supplier in the Philippines, you should always keep the following in mind to ensure your safety:

Maintain Their Distance From Open Flames or Fire

Industrial oxygen generators are used in many industries. These machines are commonly used in factories where different kinds of metal are welded or products are made. When oxygen generators are placed near open flames, they can cause a fire or explosion. The fire hazard is due to the potential for ignition of the oxygen-enriched atmosphere around the generator. If there is any source of ignition, such as a light bulb or an open flame, it can lead to an explosion or fire.

One should keep in mind that although it isn’t considered flammable, oxygen can intensify the combustion process. This means that it can cause fire to burn hotter and faster. Additionally, it plays an integral role for flames to burn and is a part of the fire triangle along with fuel and heat.

Avoid Exposure to Moist Air

Oxygen generators produce high-quality, pure oxygen to meet the needs of commercial and industrial plants. They can be used to refill oxygen tanks for medical purposes or provide a continuous supply of fresh air in environments where it might be difficult to breathe because of one reason or another.

However, owners of these machines should ensure that their oxygen generators are not exposed to moist air. Moisture or wetness can cause corrosion and rust, which will damage your equipment and reduce its lifespan.

Instruct Your Employees Not To Smoke or Use Aerosol Products

The use of an oxygen generator can cause a fire or explosion if the gas generated is mixed with other combustible materials. For this reason, it is important that you instruct your employees not to smoke or use aerosol products, including air fresheners or hair spray, near one of these machines. However, if you want to establish a smoking area in your facility, the spot should at least be 10 feet away or more from your device.

Do Not Block Intake Vents

It is essential to keep the intake vents of oxygen generators unblocked so that they can work properly. Blocking these vents will cause the generator to malfunction and produce less oxygen.

The intake vents are usually located at the bottom of the machine, on either side, or near its back. This is not always the case, though, as some models have their intakes in different locations. Regardless, the main thing to remember is that you should never block these vents, not even with a tree branch, rock, cloth, or wall. Have one of your employees check them regularly to ensure no blockages are accidentally placed here.

Always Double-Check With Your Manual and Supplier

If you’re experiencing any difficulties with your machine, make sure to double-check the manual it comes with to figure out what you can do. These pamphlets or booklets are filled with information on how you can maintain or repair your devices. However, you can also reach out to your oxygen generator supplier for those who want to ensure that nothing is amiss. Their professionals can provide you with the information you need to address the concerns you’re currently experiencing.

Where Can You Find a Trustworthy Oxygen Generator Supplier in the Philippines?

Turn to none other than Compresstech if you’re looking for a reliable supplier that offers impressive industrial oxygen generator prices in the Philippines. We have provided companies across different industries with high-grade machines and devices with various applications. A prime example of the apparatus that our team has offered them include:

Conclusion

Oxygen generators are devices that produce oxygen from chemicals. They can often be seen in various locations, such as construction sites, manufacturing plants, and mining zones. However, to ensure the safety of the people who work around these machines, it is important to follow a few safety precautions when using one.

Whether you’re looking for a machine for your fish farming or paper milling business, you can be sure that Compresstech can help you. We are one of the most trusted oxygen generator suppliers in the Philippines, and our team can help you find the machine or device you need to ensure the smooth operations of your company. Feel free to get in touch with us today to learn more!